🤠 Rodeo Roundup 2018 Week #12

🔌 Honing my MIG welding skills. 🚜 Building new top bar beehives 🐝

🔌 Welding Class #8

This week I completed my test weld but left the actual testing for next class. Adam, on the other hand, completed his test and passed. Congrats Adam!

I returned to MIG welding as I wasn't happy with my ability to produce a quality weld. Especially in the thinner 16 gauge metal. I had trouble staying on the seam between the 2 pieces I was welding together. And my speed of travel was inconsistent, to the point that I lingered too long in one spot and burned through the metal.

This week I started out no better. For the life of me, I couldn't see where I was going. It seemed that the bright light of the glowing wire tip didn't throw enough light around to see ahead. I tried adjusting my welding mask once more but neither a darker setting nor a brighter setting improved my vision. I placed my face practically on top of the welding gun, as close I could get, but that didn't help either.

It wasn't until I marked the seam to be welded with soapstone, which provides additional contrast, that my welds improved. The white marks show up much better in the light of the glowing tip than the surrounding gray metal.

With practice, my speed of travel also improved but it still wasn't great. Next class, I'll do what Adam did and reduce the voltage (and wire speed) so that I can move slower. That should reduce the risk of burn through.

🚜 On the Farm

We started a family project over the weekend. Spring is almost here, and we would like to expand the number of bee colonies beyond the 3 we currently have. 🐝

Spring is the time that colonies can split in 2, and we want to be ready with hives for the new ones. Plus we have an old (crappy) hive from Les Crowder we would like to replace.

With room for 6 top bar hives on our stands and 2 in place, we had room for 4 more. Our plan is to transfer the colony in Les's hive and the colony currently in the nuc hive into new hives. That leaves us with 2 empty additional hives. We'll probably sell Les's hive. We'll keep the nuc around to catch wild swarms with.

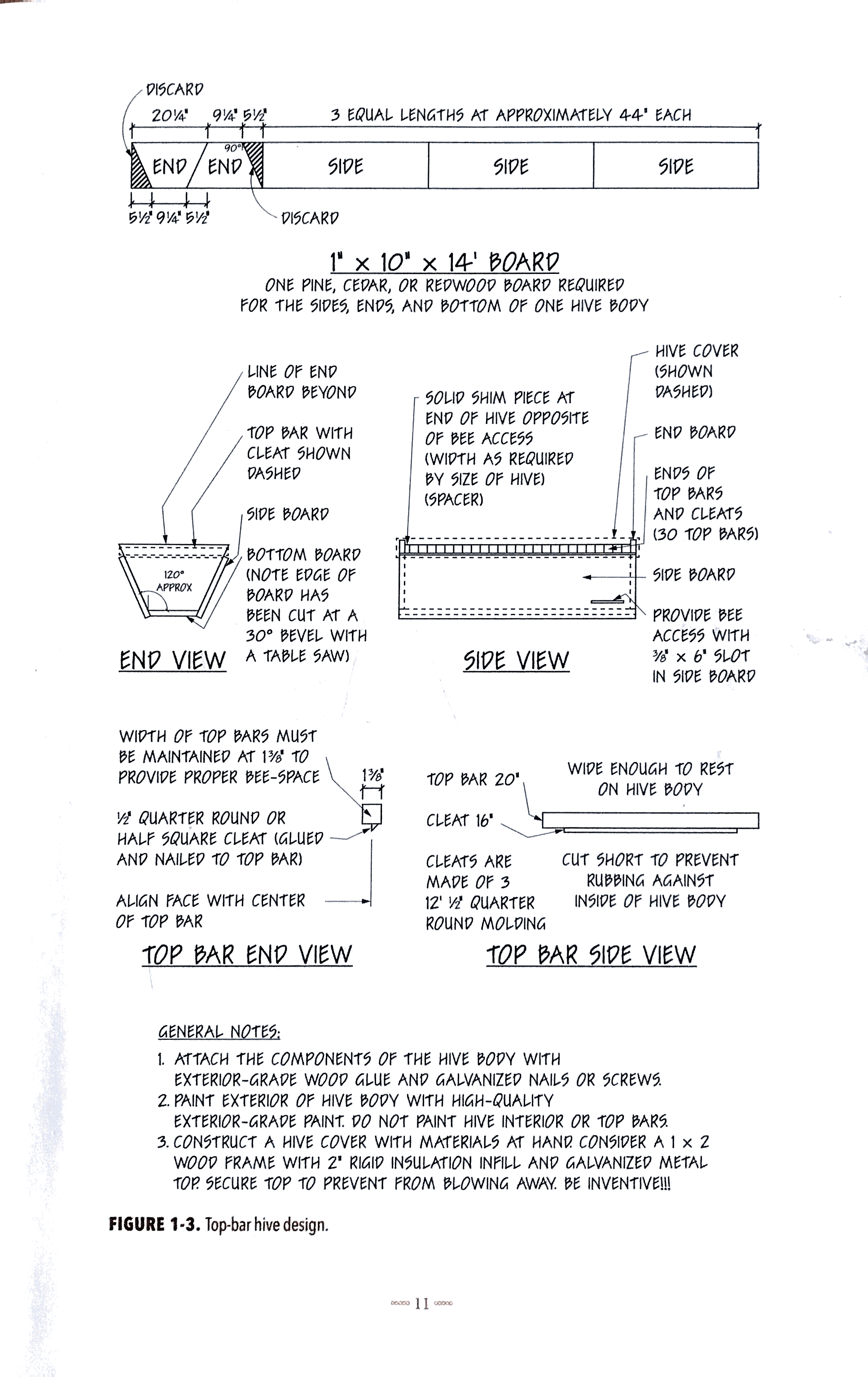

Our hives are built of the horizontal top bar hive plans from Top-Bar Beekeeping: Organic Practices for Honeybee Health by Les Crowder.

It took us 2(!) trips to Home Depot to get all the materials. The math I did in my head on our first trip was incorrect and I thus had to go back for more.

I was in charge of the cutting and routing, Tatyanna painted, while Casper glued cleats to the bars.

The top bars are made from 20.25" 1x2 stock. Each bar got a small notch to align the bar with.

The cleats are cut from leftover stock. Cut 1x stock at a 45º angle to create a cleat. Angle the blade to 90º and cut another cleat. Then repeat the 45º cut and so on. Time-consuming and dusty work!

Casper put glue on a cleat, stuck it on a bar and tacked it in place with a brad nailer. Look at the stack he did.

To be continued next week…

Photo by Boris Smokrovic / Unsplash